A Systematic Approach from Fragrance Innovation to Production Control to Solve Scent Fading

For laundry detergent brands, long-lasting fragrance has become a critical differentiator for market success. However, achieving a consistent scent from the washing machine to the wardrobe presents three core challenges: fragrance volatility, formulation incompatibility, and production inefficiencies. This guide provides an in-depth analysis of how Gar Aromas’ systematic technical solutions precisely address these challenges, empowering your product with enduring and superior scent competitiveness.

一、Precision in Fragrance Selection and Customization

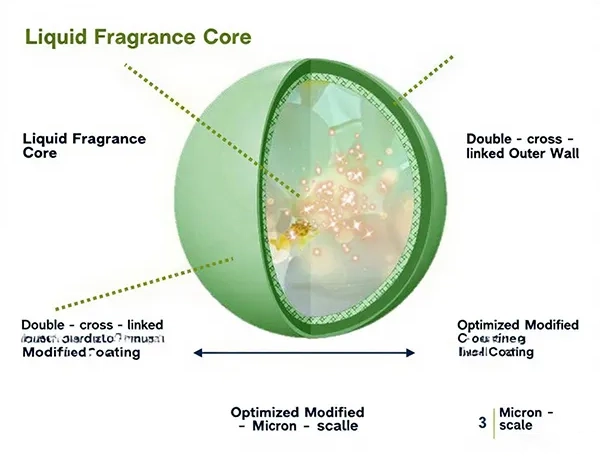

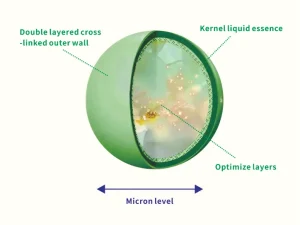

Microencapsulation Technology: A core technology at Gar Aromas. We encapsulate fragrance oils within polymer shells, creating micron-sized capsules. These capsules withstand rinsing during the wash cycle, only releasing the fragrance upon friction, wearing, or ironing of the fabric. This “time-release” and “triggered-release” mechanism significantly extends the fragrance longevity from a few hours to several days or even weeks.

High-Substantive Fragrance Bases: Tailored to the charge characteristics of different fibers (cotton, polyester, blends), we offer specially modified fragrances. Their molecules exhibit high affinity for fabric fibers, effectively resisting being washed away.

二、Synergy and Optimization of the Formulation System

Fragrance stability within the formulation is a prerequisite for longevity. An improper system can lead to fragrance degradation, separation, or rapid evaporation.

1.pH Value Management: Fragrances are highly sensitive to pH. Gar Aromas recommends stabilizing the final detergent’s pH within a neutral to slightly alkaline range of 7.0 – 8.0. Excessively high alkalinity (pH > 10) can cause saponification and hydrolysis of key fragrance molecules like esters, permanently altering the scent profile and weakening its staying power.

- Ingredient Addition Sequence and Temperature Control: Fragrance should be added during the mid-to-late stages of ingredient compounding, at a low temperature (< 40°C). Avoid adding fragrance during the initial introduction of surfactants, alkalis, or under high-shear mixing at elevated temperatures to prevent emulsion instability or fragrance loss/chemical degradation due to heat.

- Compatibility with Surfactants: Cationic surfactants (e.g., softener components) are often incompatible with anionic surfactants, easily causing system flocculation, which can carry fragrance oils out of solution. Gar Aromas provides fragrance solutions with excellent compatibility across various ionic surfactant types (nonionic, anionic, amphoteric, cationic), ensuring even dispersion within the system.

- Impact of Preservatives: Certain preservatives (e.g., formaldehyde-releasing agents) can react with fragrance molecules, causing discoloration or odor changes. When selecting a preservative system, conduct compatibility testing with the Gar Aromas technical team; we can recommend compatible fragrances or alternative preservative solutions.

三. Precise Control in Production Processes

Precision in production is key to ensuring a perfect lab-scale formula is successfully replicated in commercial products.

1.Mixing Intensity and Homogenization Process: Gentle yet thorough mixing is crucial for uniform fragrance dispersion. Excessive shear force can damage microcapsules or break the emulsion. We recommend low-speed homogenization to ensure complete integration without separation.

2.Accuracy in Weighing and Dosing: Fragrance is a high-potency ingredient. Minor weighing inaccuracies (even 0.1%) can lead to significant deviations in the final scent profile. Employ high-precision weighing systems and establish strict dosing verification protocols.

3.Packaging and Storage Recommendations: Fragrance oxidation and evaporation can begin after product bottling. Gar Aromas recommends:

- Use opaque containers or UV-resistant materials to prevent light-induced fragrance degradation.

- Ensure packaging has excellent seal integrity to minimize fragrance loss through the cap during shelf life.

- Store products in a cool, dry place, avoiding high-temperature environments.

Why Choose Gar Aromas as Your Fragrance Partner?

In-Depth Technical Support: We are more than a supplier; we are your technical partner. Our application lab offers comprehensive formulation compatibility testing (FTIR/DLS analysis), accelerated stability testing (heat, cold, light), and production process optimization advice.

Customized Solutions: We provide unique fragrance customization based on your specific formulation system, target cost, and production process, solving any longevity challenges you encounter.

Innovation and Sustainability: Gar Aromas continuously invests in R&D for cutting-edge areas like microencapsulation and sustained-release technologies, offering eco-friendly and biodegradable fragrance options aligned with market trends.

Contact the Gar Aromas expert team today for a free technical consultation and build an unbeatable competitive edge with long-lasting fragrance for your detergent products!