72H ScentLock Microcapsule Fragrance for Fabric Softener

Microcapsule fragrance in laundry detergent and fabric softener, long-lasting scent microcapsules attached to fabric surface 。

- 72H+ Scent Retention – Industry-leading fragrance longevity

- Smart-Release Mechanism – Activated by fabric movement

- Eco-Engineered – Sustainable polymer coatings

- encapsulated fragrance for fabric conditioner

Fragrance Encapsulation Technology Description

Microcapsule Fragrance: Definition, Technology & Applications

I. Core Concept

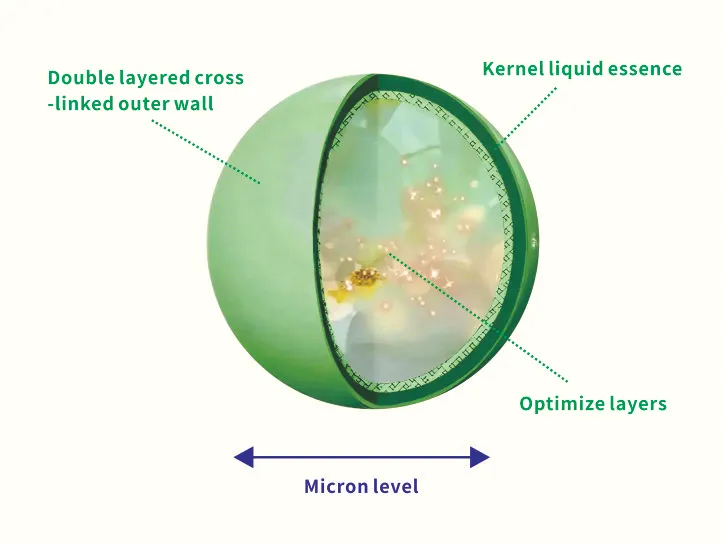

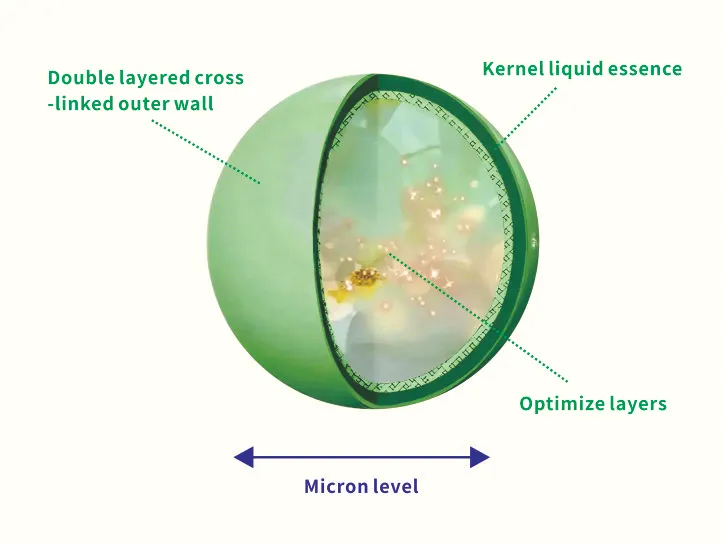

II. Physical Form & Structure

-

Core Material (Payload): The encapsulated fragrance essence, including floral fragrances, fruity notes, resinous accords, or other scent types tailored to specific applications. -

Wall Material (Shell): A specialized coating (e.g., polymers, gums, or proteins) that seals the core. Must be non-toxic, chemically stable, and engineered with precise viscosity, permeability, mechanical strength, and flexibility to ensure controlled release.

III. Key Features & Advantages

-

Enhanced Stability The sealed capsule structure significantly reduces fragrance evaporation, extending shelf life and ensuring long-term scent retention during storage and application. -

Controlled Release (Sustained Fragrance) Delivers slow-release aroma diffusion, prolonging the fragrance lingering effect and improving user experience over time. -

Protection of Sensitive Compounds Shields heat-sensitive, light-sensitive, or oxidation-prone aroma molecules from degradation caused by environmental factors (e.g., UV rays, high temperatures). -

Physical Form Transformation Converts liquid or semi-solid fragrances into free-flowing microcapsule powders, optimizing dispersion stability in dry or water-based formulations.

IV. Diverse Application Fields

-

Textiles & Paper Products: Infused via finishing processes to impart long-lasting fabric fragrance or scented paper (e.g., laundry detergents, aromatic tissues). -

Food Industry: Enhances food aroma and palatability by encapsulating flavorings, elevating product appeal. -

Cosmetics & Personal Care: Integrated into perfumes, skincare products, makeup, and hair care formulations (e.g., shampoos, conditioners) to boost fragrance longevity and user satisfaction. -

Industrial Applications: Utilized in plastics, rubber, leather goods, coatings, paints, and inks for functional or olfactory purposes.

Data Sheet

| Characteristic | Result | Specification ] | MU | Method | ||

| Appearance | Conforms | [ Viscous and turbid liquid ] | NA | CQ-012 | ||

| Color | Conforms | [White to yellowish-white ] | NA | CQ-001 | ||

| Aroma | Conforms | GAR | NA | CQ-022 | ||

| Relative Density (d20/20) | 1.018 | [ 1.005 – 1.035 ] | NA | CQ-010 | ||

| Relative Density (d20/20) | 1.015 | 1.002 – 1.032 ] | NA | CQ-010 | ||

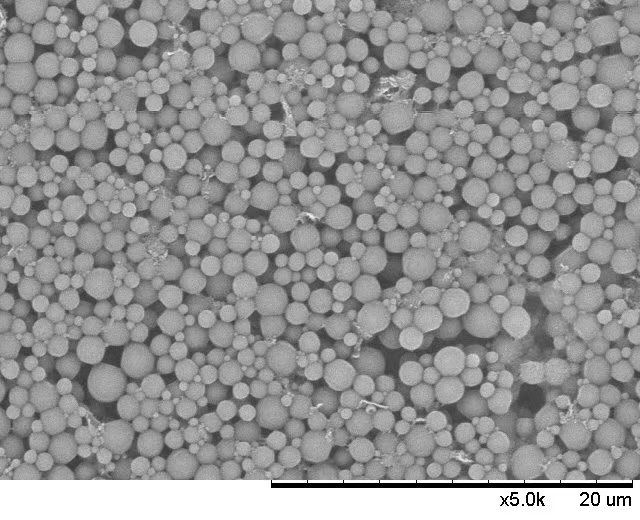

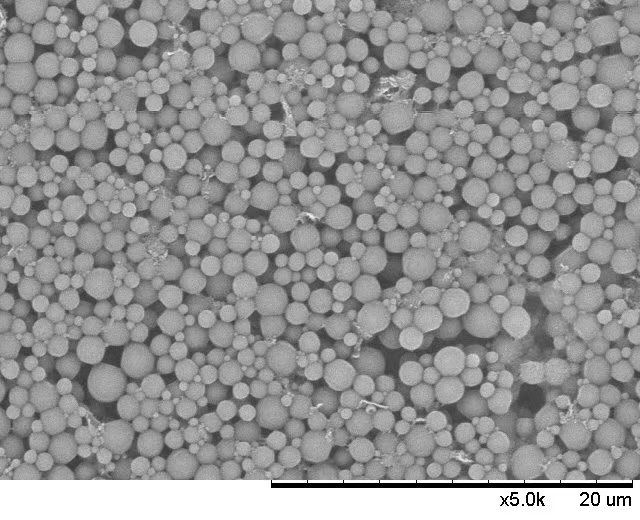

| Particle Size of Daily Chemical Microcapsules | 14.5 | [ 10.0 – 23.0 ] | µm | CQ-163-1 | ||

| Particle Size (>50μm) | 0 | [<= 25.0 ] | % passes | CQ-163-2 | ||

| Free Formaldehyde Content | 59 | [<= 100 ] | Ppm | CQ-161 | ||

| pH Value | 5/7 | [ 6.0 – 7.5 ] | NA | CQ-107-2 | ||

| Dry Content Determination (3g – 130°C) | 34.2 | [ 6.0 – 7.5 ] | % | CQ-162 | ||

| Solubility | Water-soluble | |||||

| Flash Point | > 100 °C / > 212 °F | |||||

| Storage Conditions | Unopened, store in a dry place, optimal storage temperature is 11-30°C/52-86°F | |||||

| Usage | In fabric care, textiles and other products | |||||

Get a Free Sample of Your Custom Fragrance

Will microcapsule fragrance separate in laundry detergent?

Related Products

Related News

As a perfumer with over a decade of experience in the daily chemical fragrance industry, I deeply understand that the […]

In the competitive home care, detergent, and fragrance markets, scent beads (or fragrance beads) have become a star product, widely […]

The Revolution of Long-Lasting Scent The quest for a durable, long-lasting fragrance in laundry care has been significantly advanced by […]

Why Southeast Asia Is Emerging as a Key Market for Laundry Scent Boosters Driven by hot and humid climates, rising […]

As a perfumer, I’m often asked by international clients: “How to choose a reliable cosmetic fragrance?” Here are 5 key […]

Why Vietnam Is a Key Market for Fabric Softener Fragrance Development Vietnam has emerged as one of the most dynamic […]

Thailand has long been the trendsetter for the Southeast Asian fabric care market. Currently valued at US$402 million with a […]

A Systematic Approach from Fragrance Innovation to Production Control to Solve Scent Fading For laundry detergent brands, long-lasting fragrance has […]